The precise planning and execution of a complicated operation is usually referred to as logistics. Logistics is the administration of the progression of items between the place of origin and the point of consuming to fulfill customers’ needs or partnerships in general marketing prudence.

In logistics firms, physical products such as materials, hardware, supplies, and food and other consumable items may be managed.

For the most part, physical logistics entail a combination of information flow, material handling, creation, packing, stock, transit, warehousing, and regular security. We’ll be covering many sorts of logistics here.

The method that a firm uses to facilitate its supply chain activities is logistics or logistical planning. It includes a diverse range of projects and activities.

For example, supervising how raw materials or data sources are procured and transported to the company, how stock and data sources are stored at the company’s offices, and how stock is transferred both within and outside the company.

Different Types of Logistics

Here is the latest list of all types of Logistics that you should know about.

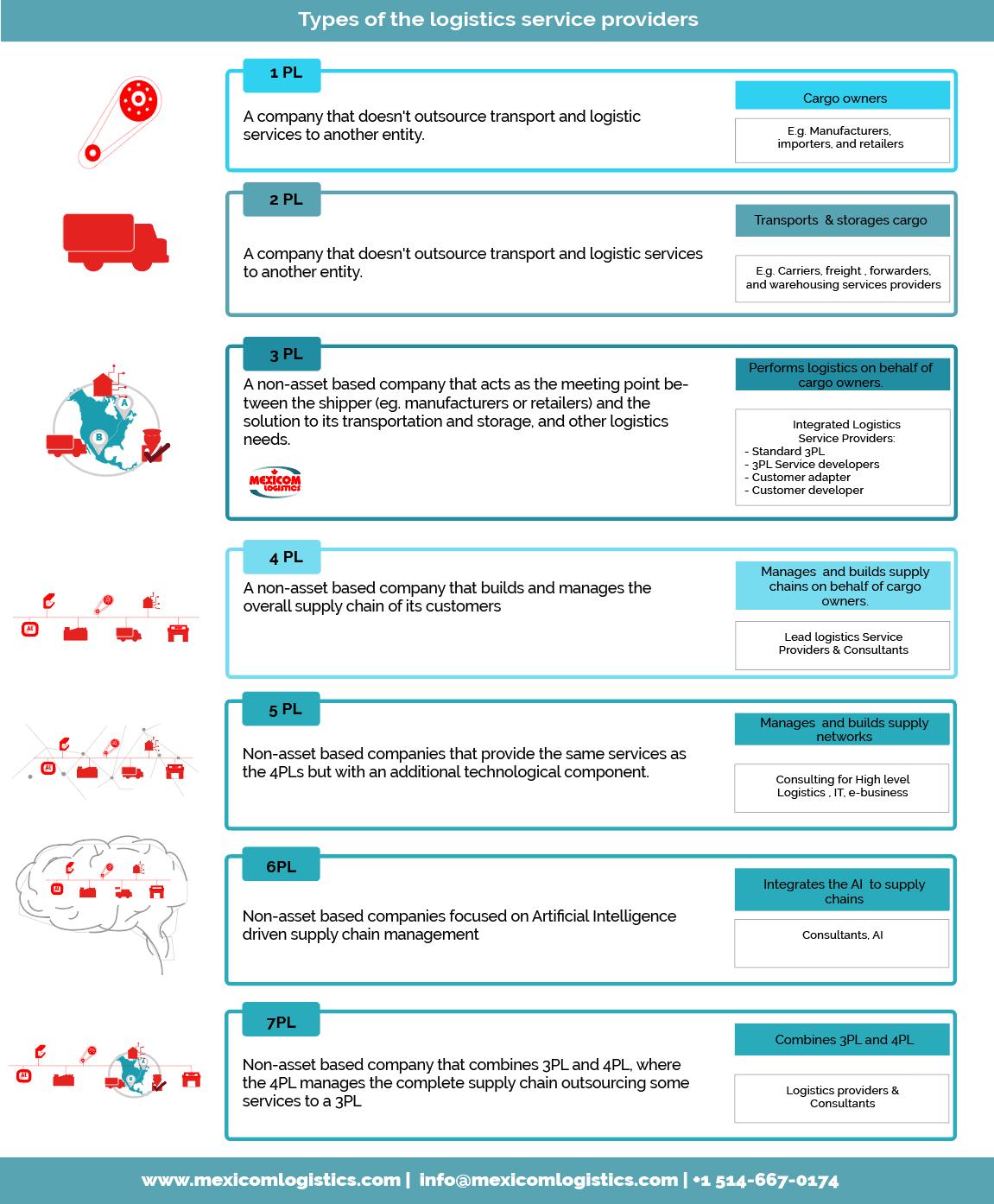

1. Inbound Logistics

Inbound logistics refers to the internal logistics tasks and exercises that businesses must complete in order to continue operating. Inbound logistics usually refers to the strategic activities performed by businesses that work upstream. When it comes to the supply chain, it refers to the relationships between parties who work upstream of the provided company. The parties who work upstream may vary substantially in their specific duties depending on the business.

Consider being a vehicle factory, for example. Inbound logistics for the manufacturer would include acquiring raw material data sources (sheet metal, glass, wire, plastics, and so on), storing materials in preparation for and throughout the assembly process, and dealing with the flow of finished vehicles leaving the facility.

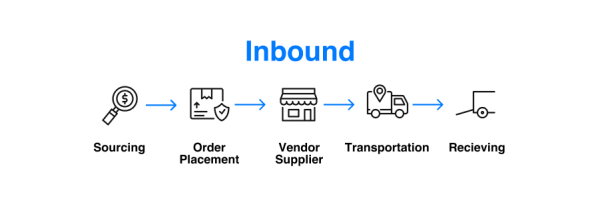

2. Outbound Logistics

The errands and exercises involved in getting the goods to the final client are referred to as outbound logistics. Players who work significantly downstream, often the last party in the supply chain, are subject to such strategic duties. Storage of manufactured stock, delivery of created products to retail locations, and, in some cases, shipping and handling are all included in the responsibilities.

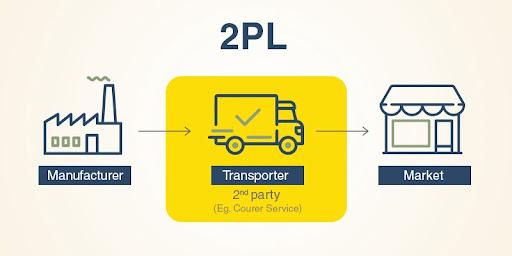

3. First-Party Logistics (1pl)

The manufacturer can manage the shipment and warehousing in this instance. 1PL firms will have their own fleet of vehicles. Few businesses utilize this strategy these days since outsourcing allows them to be more flexible.

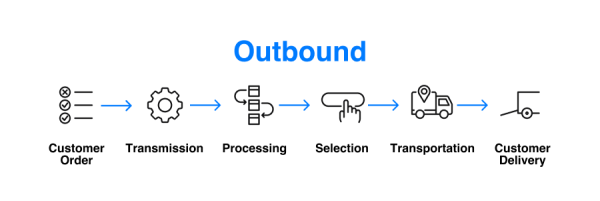

4. Second-Party Logistics (2pl)

In this situation, the supplier is exclusively responsible for the supply chain’s transportation. Shipping and transportation firms are examples of this strategy.

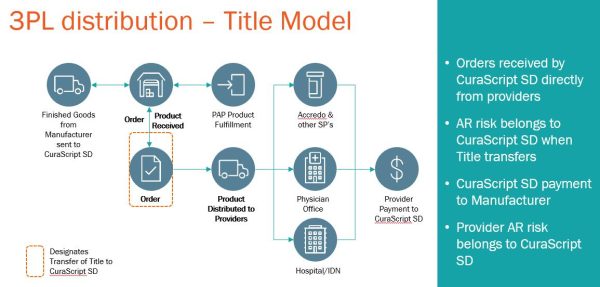

5. Third Party Logistics

For entrepreneurs, third-party logistics may be perplexing. All parts of the supply chain that plan, execute, and regulate the movement of goods and services to satisfy customer needs are referred to as logistics. Third-party logistics refers to the use of a third-party company to outsource logistical services.

These services can cover all managerial exercises as well as the many ways in which an organisation moves resources from one place to the next. Tasks, transportation, warehousing, and manufacturing are all included.

6. Fourth Party Logistics

A fourth-party logistics provider, or 4PL, takes third-party logistics to the next level by managing resources, innovation, technology, infrastructure, and even external 3PLs to create, manufacture, and provide business supply chain solutions.

A 4PL solution comprises 3PL as well as logistics strategy, freight sourcing strategies, network analysis and design, consulting, business planning, change management, project management, inventory planning and management, and inbound, outbound, and reverse logistics management.

7. Fifth-Party Logistics (5pl)

This is a step up to 4PL’s consulting level. The provider in this situation combines the shipping requirements of numerous 3PLs. As a result, market dominance may be used to negotiate advantageous carrier prices. Some businesses, for example, utilize 5PL to manage their whole supply chain. Under this arrangement, the provider sources services and negotiates relevant contracts on your behalf.

8. Beyond 5pl

It was uncommon to outsource logistics before to the 1980s. Outsourcing began as a reaction to changing industry rules. The use of new technology has also had a substantial impact on supply chains. As a result, 3PL, 4PL, 5PL, and other services were introduced to satisfy new demands.

Further changes in the sector became unavoidable when artificial intelligence (AI) was developed and used. Although some see 10PL services as a possibility in the future, they have yet to be operationalized and commercialised. Here are a few things to look forward to in the near future:

9. Sixth-Party Logistics (6pl)

These should allow for environmentally friendly supply chain management. The utilisation of resources and the renewability of activities will be the main performance metrics in this niche. They may also think about equitability in supply chain management. It is expected that the providers would be held to high environmental and social responsibility standards.

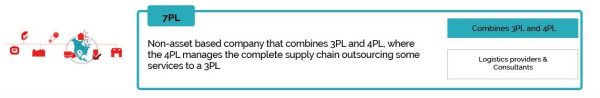

10. Seventh-Party Logistics (7pl)

This hybrid of 3PL and 4PL services combines full-service fulfilment, warehousing, and transportation into one convenient package. The 7PL provider has the strategic management skills of a 4PL provider, with the added benefit of owning and controlling certain physical assets, such as a warehouse, that a 3PL provider would have.

11. 8pl And Beyond

Beyond 7PL, the client’s supply chain management setup represents their goals and business strategy. In an 8PL situation, a high-level committee would be anticipated. The group would then look into industry practises and make recommendations to close the gaps. At the 9PL level, the goal is to find crowd-sourced solutions that satisfy last-mile delivery needs. Lyft and Doordash are two examples. Meanwhile, all of the 10PLs employ artificial intelligence to make the supply chain self-aware and capable of running itself.

12. Distribution Logistics

Organizing errands, control, and all operations relating to the movement of goods and information between manufacturing firms and clients is part of distribution logistics. The connection or relationship between market and production is distribution logistics (also known as transport logistics or sale logistics).

The zone comprises all procedures related to product distribution, from manufacturers to clients. Final end consumers, wholesalers, distributors, and processors are all possible customers. It guarantees that produced products and services reach customers in a safe and timely manner.

13. Reverse Logistics

Reverse logistics refers to a collection of operations carried out after an item has been sold in order to recoup its value and bring the item’s lifespan to a close. It usually entails returning an item to the manufacturer or merchant, or sending it to be overhauled, repaired, or repurposed. It’s also known as reverse logistics, aftermarket supply chain, or reseller’s aftermarket logistics.

Reverse logistics is the area of supply chains that deals with anything that is returning inwards or travelling backwards via the supply chain. As a result, the term is changed to reverse logistics.

14. Aerospace Logistics

Aerospace logistics is the technique of choice when you require accelerated international shipping services. When compared to ocean freight, air freight requires less packing and insurance. When time and resources are taken into account, it may be less costly to transport. Air freight moves rapidly as well. Similar to local ground transportation, packages can reach in a couple of hours. When you require accelerated shipment, air freight provides you a lot of options and is an important part of any logistics strategy. When combined with truckload transportation, aerospace logistics can carry specialised freight across the country or around the world in record time.

15. Truckload Shipping

Truckload shipping is one of America’s most used logistical strategies. This comprises a wide range of services, including:

- Services for LTL Freight

- Services for Oversize Freight

- Transport Services for Industrial Machinery

- Services for Expedited Freight

You should seek for a firm that can deal with a wide range of scenarios. Do you require the services of a complete truckload carrier? Do you require the services of a less-than-truckload carrier? How fragile are your possessions? Are these items that should be avoided? A full truckload carrier is your best choice if you’re transporting sensitive or fragile products. Because there are no additional stops, the shipping will be speedier, and the goods will not be touched before it arrives at its destination. Of course, there may be occasions when you need to send less, so having a shipping partner that can provide LTL shipping services is essential. When you need to move items across the country but don’t have a tight deadline, truckload shipping is the way to go.

16. Rail Freight Logistics

Rail freight and truckload shipping and aircraft logistics are an important part of the US logistics system. However, because managing the rail system is a huge undertaking, it’s a good idea to engage a freight firm that specialises in intermodal or multimodal transportation. A third-party logistics business may handle everything for you and send you a single bill. As a result, your company may use all modes of transportation, including the rail system, without having to get additional permissions and licences. You will have less work to do as a result of this.

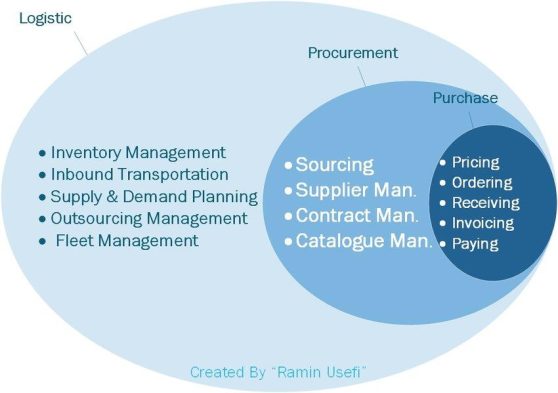

17. Procurement Logistics

When raw materials and parts needed for production are purchased from suppliers, procurement logistics is the flow of commodities. Many firms are actively pursuing production by procuring the necessary materials in only the necessary amounts at the necessary times (the shift to just-in-time production) because it is directly linked to reducing inventory costs. This field did not attract much attention before, but now that small-lot production of a variety of models is the main type of production, many firms are actively pursuing production by procuring the necessary materials in only the necessary amounts at the necessary times (the shift to just-in-time production).

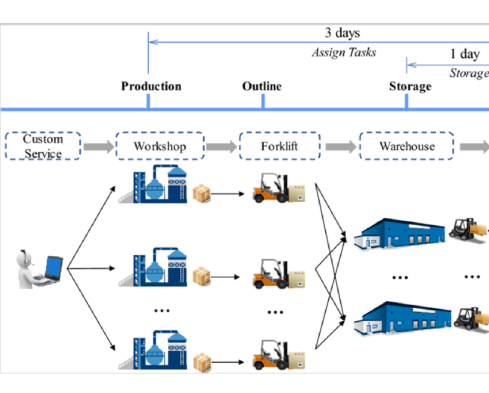

18. Production Logistics

The administration of acquired components and supplies, distribution within a plant, product management, packing, and shipment to warehouse are all examples of production logistics. By seamlessly connecting procurement logistics and sales logistics, delivery management, warehouse dispatch management, and shipping management can be optimised, and the status of delivery vehicles can be monitored.

19. Sales Logistics

The term “logistics” usually relates to the logistics of sales. Previously, the norm was shipping from delivery centres and logistics warehouses to distribution locations like wholesalers and retailers. However, owing to internet purchasing and e-commerce, direct delivery now accounts for a significant portion of this volume. Higher efficiency in transportation and delivery and shrinking inventory are essential for delivering the necessary goods to the necessary people in the necessary quantities at the necessary time, whether through delivery centres and logistics warehouses or direct delivery from production sites. This, in turn, helps to improve client satisfaction.

20. Recovery Logistics

Forward logistics is defined as the movement of commodities from production to consumption as represented by procurement logistics, production logistics, and sales logistics utilising the body’s circulatory system. Recovery logistics, often known as reverse logistics, is the process of recovering and recycling items, containers, and packaging that have served their purpose. In recycling-oriented cultures, attention is put on this movement, similar to the recycling logistics detailed below.

21. Recycling Logistics

Recovery and recycling of empty cans, plastic bottles, and old paper are common instances of recycling logistics. Containers, packaging, outdated computers, and printer cartridges may all be recycled the same way. Recycling logistics has become more important in recent years to protect the environment and efficiently use resources such as minor metals.